Construction Equipment Transportation Services

Engineering-Level Solutions for Heavy & Oversized Machinery

We specialize in transporting construction and engineering equipment that exceeds standard size and weight limits. From on-site assessment and transport planning to secure loading and final delivery, our team ensures safety, efficiency, and full compliance at every stage.

Certified Construction Equipment Transportation Solutions

Our construction equipment transportation services are designed specifically for heavy and out-of-gauge machinery. Each shipment begins with a technical assessment of equipment dimensions, weight distribution, and loading constraints. Based on this assessment, we develop a customized transport plan that prioritizes safety, efficiency, and cost control.

We handle a wide range of construction and engineering equipment, including excavators, bulldozers, cranes, loaders, rollers, and other heavy-duty machinery used in infrastructure, mining, and industrial projects.

On-site measurement and technical evaluation

Transport plan design based on equipment size and weight

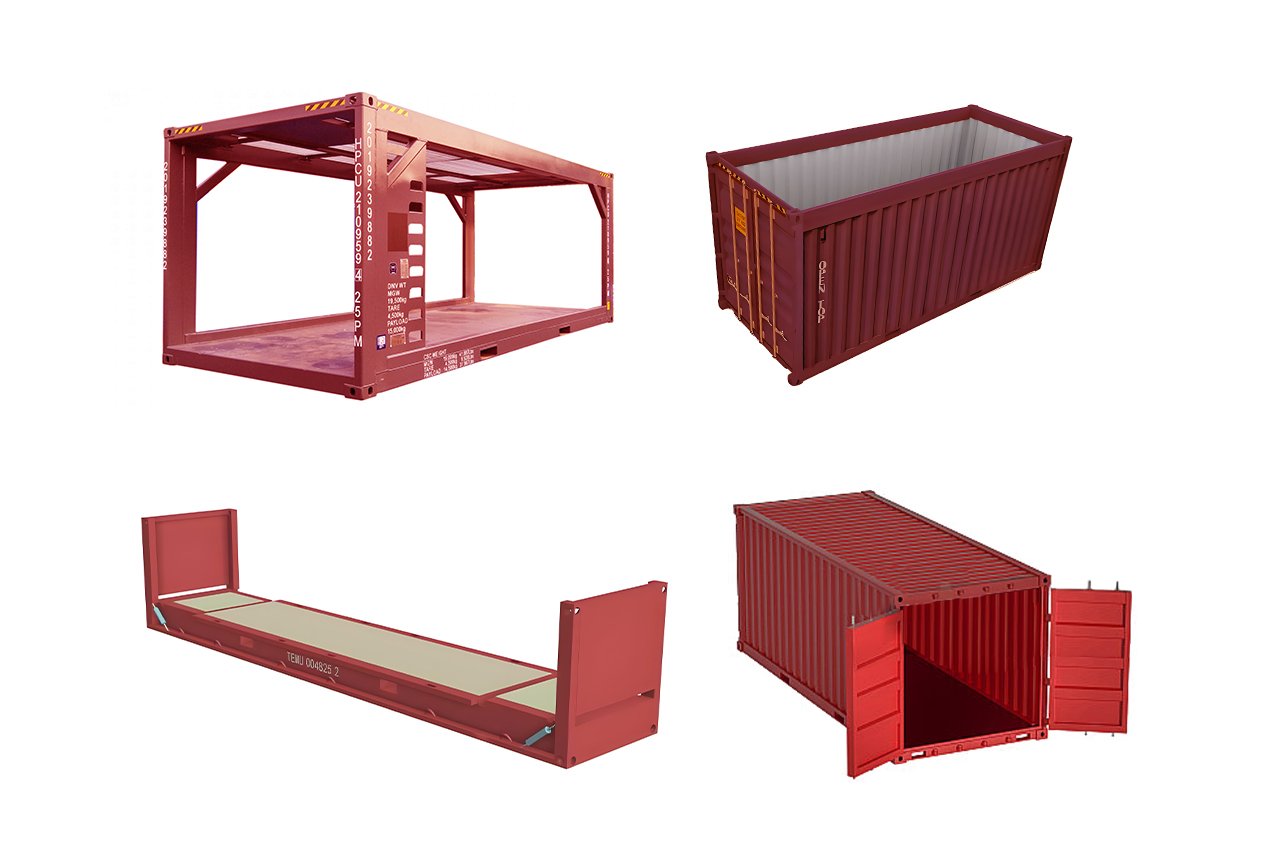

Flat rack, open top, or specialized transport solutions

Professional securing, lashing, and cargo protection

Coordinated delivery aligned with project schedules

Why Choose Our Construction Equipment Transport Services

Construction equipment transportation involves high risk if handled without proper expertise. Improper loading, insufficient securing, or incorrect route planning can result in equipment damage, delays, or costly project disruptions.

Our team approaches each shipment as an engineering project rather than a standard logistics task. We combine technical expertise, specialized transport equipment, and proven project experience to ensure that heavy machinery is moved safely and efficiently under real-world conditions.

Engineering-Focused Planning

Every shipment is supported by detailed transport planning, including load distribution analysis and equipment selection.

Bentlee Construction machinery transportation

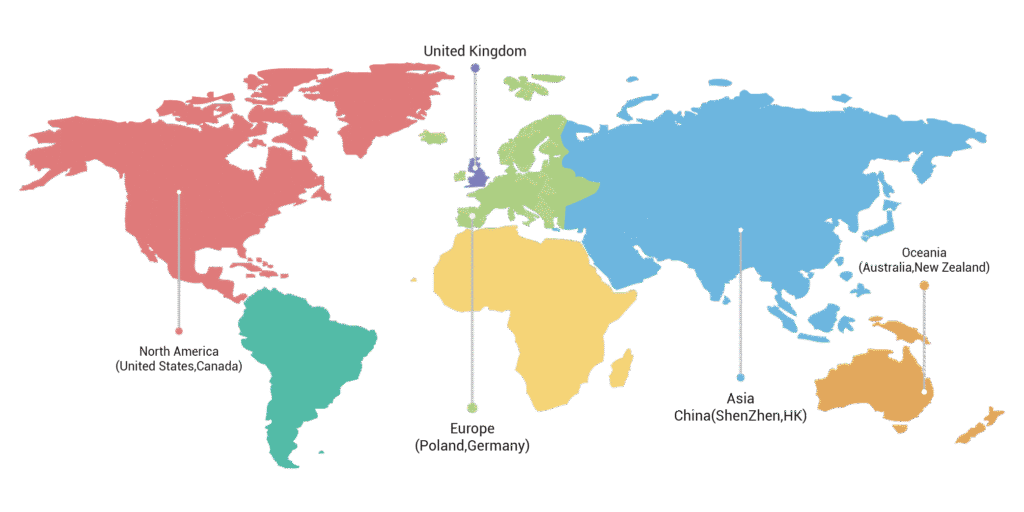

One-stop service for OOG cargo bundling, Chinese inland trailers, hoisting, and special container transportation, an expert in logistics solutions for overall factory relocation

Measurement

Door to door measurement of goods size

Transportation Solutions

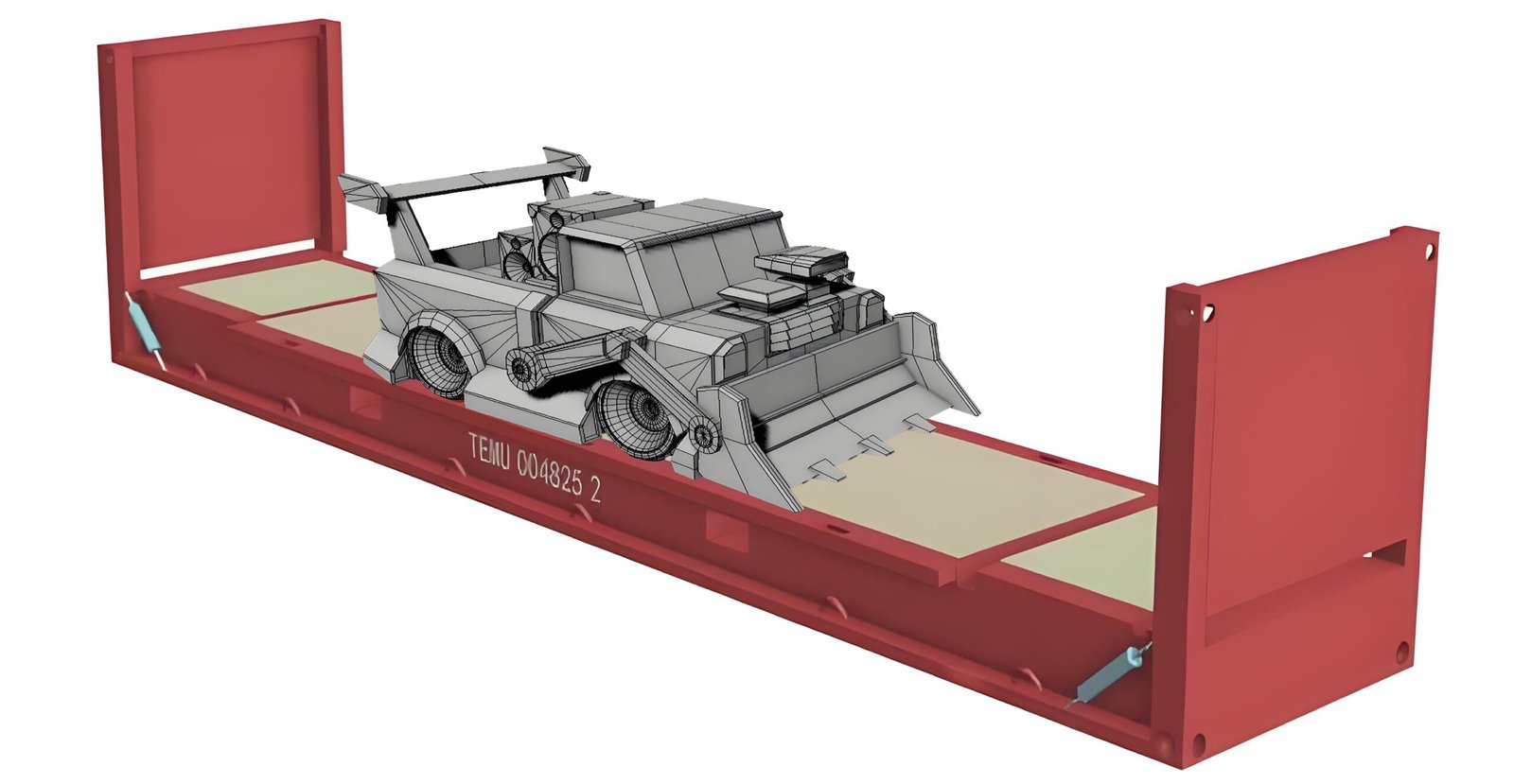

Transportation plan,Such as cabinet type, loading, and 3D loading model

Cabinet type

Cabinet type, 3D loading model

Route Planning

Booking, route planning, and preliminary preparation Preparation before container loading

Container loading

special trailer, vacuum packaging, etc,Binding and fixation, wooden box packaging, ultra-low flatbed trailer

Customs clearance

Customs declaration and release,DAP, DDP post delivery service

Construction machinery transportation

The transportation schedule for construction machinery involves meticulous planning and coordination to ensure the smooth movement of heavy equipment and vehicles required for construction projects. Below is an outline of the typical steps:

- Equipment Assessment:

Begin by evaluating the machinery needed for the project. This includes identifying the specific types—such as excavators, bulldozers, cranes, loaders, and dump trucks—and determining their sizes, weights, and transportation requirements. - Logistics Planning:

Once equipment requirements are confirmed, develop a logistics plan covering the optimal transportation methods, routes, and timelines. Key considerations include distance, road conditions, special permits or restrictions, and the availability of specialized transportation services. - Coordination with Transport Providers:

Partner with experienced transport providers who have the expertise and equipment to handle heavy machinery. Confirm their availability and secure the necessary transportation resources. - Permits and Regulatory Compliance:

For oversized or overweight loads, secure the required permits and ensure compliance with regulations, including designated travel routes and restricted travel times. Allocate sufficient time for the permitting process. - Loading and Securing:

Safely load machinery onto transport vehicles using cranes, ramps, or other appropriate methods. Ensure the equipment is properly fastened and balanced to prevent damage during transit. - Transportation Execution:

Transport the machinery according to the agreed schedule, whether for local or long-distance delivery. Maintain strict adherence to safety regulations throughout the journey. - Unloading and Site Preparation:

Upon arrival, unload and position machinery at the designated locations. Use lifting equipment as necessary and prepare the site by leveling the ground and ensuring proper access for operation. - Schedule Updates:

Remain flexible to accommodate project changes or unexpected delays. Regular communication with transport providers and project stakeholders ensures timely adjustments and that machinery arrives in the correct sequence for project needs.

In summary, an effective construction machinery transportation schedule requires careful planning, seamless coordination, and disciplined execution to achieve safe, timely, and efficient delivery of heavy equipment—minimizing delays and maximizing operational efficiency.

Customer reviews about Bentlee

User reviews from trustpilot

More Order Fulfillment Services Shipping from China

FAQ

OOG (Out of Gauge) cargo refers to oversized, overweight, or irregularly shaped shipments that cannot fit into standard containers. Common OOG solutions include Flat Rack and Open Top containers.

OOG containers are typically used for heavy machinery, construction vehicles, wind power equipment, steel structures, timber, long pipes, and precision instruments.

Yes. We provide professional reinforcement solutions such as wooden crating, steel wire lashing, vacuum packaging, and waterproofing to ensure cargo safety.

The cost mainly depends on cargo dimensions, weight, container type, shipping route, and reinforcement requirements. A detailed quotation will be provided after reviewing your cargo details.

No. With over 10 years of customs clearance experience and a 98% clearance success rate, we ensure smooth and reliable clearance for oversized and special cargo.

We offer end-to-end logistics solutions including transport planning, warehousing, crating and reinforcement, inland + sea transportation, customs clearance, and door-to-door delivery.