Plant relocation transportation

Seamless Plant Relocation Transportation Solutions expert: Trust us for a Smooth Move!

Bentlee Plant relocation transportation

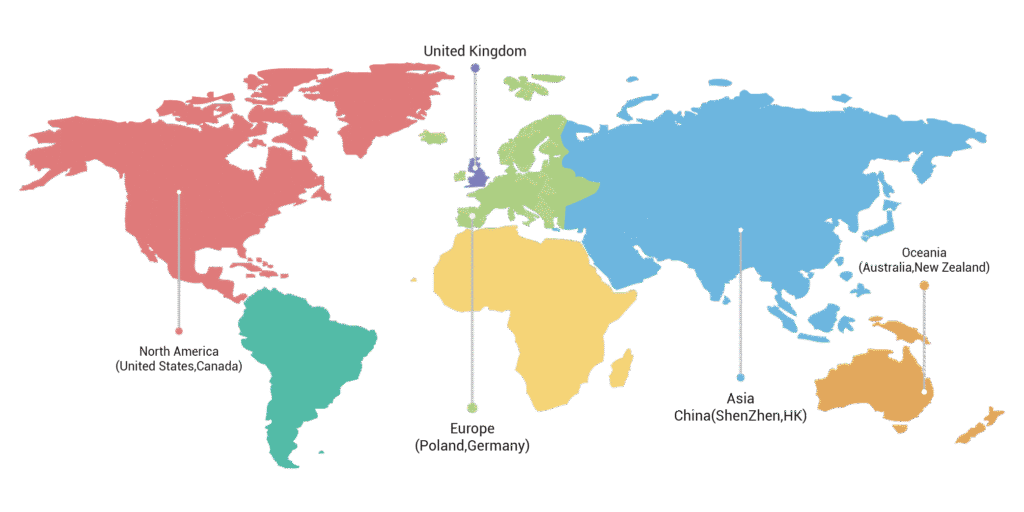

One-stop service for OOG cargo bundling, Chinese inland trailers, hoisting, and special container transportation, an expert in logistics solutions for overall factory relocation

Measurement

Door to door measurement of goods size

Transportation Solutions

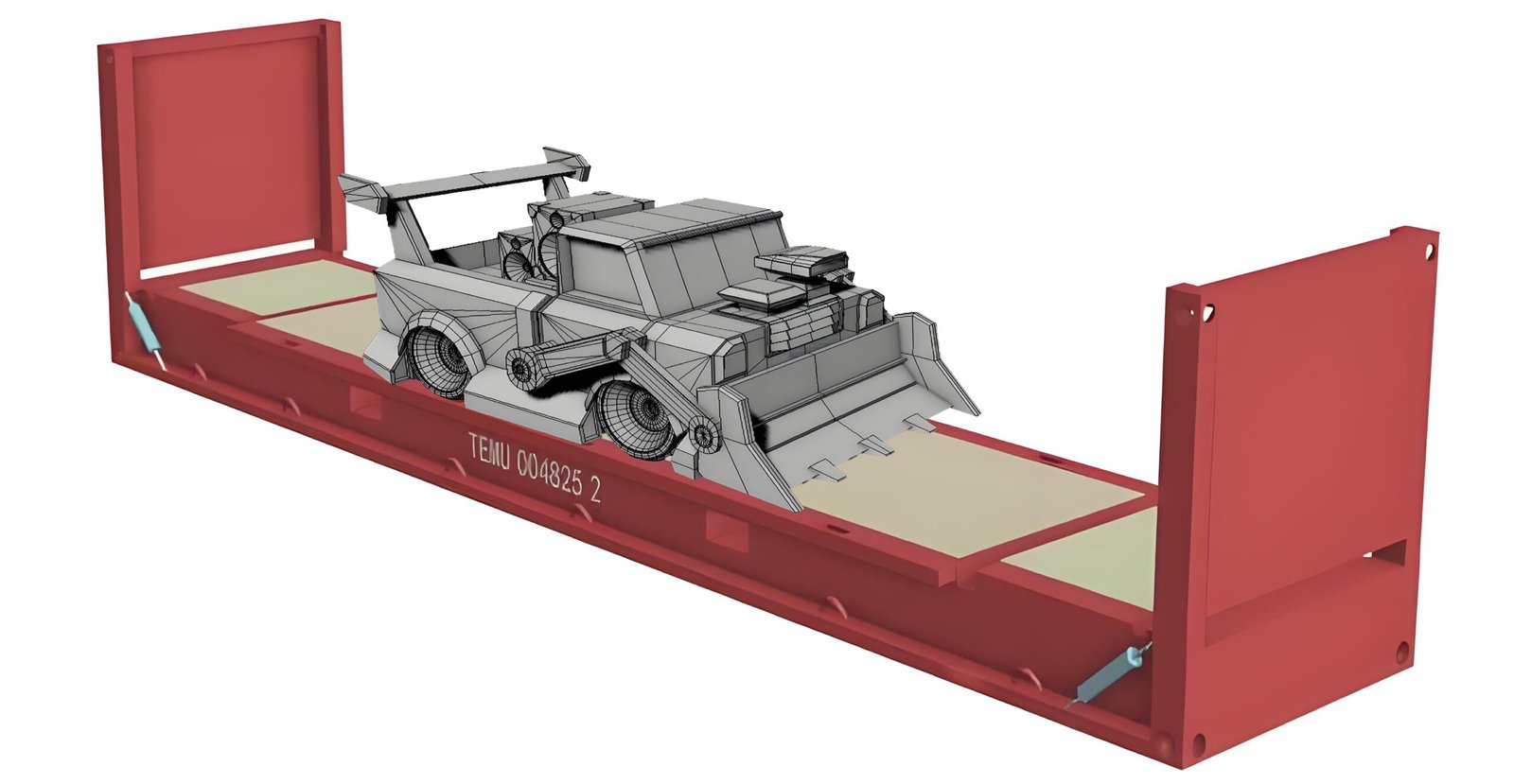

Transportation plan,Such as cabinet type, loading, and 3D loading model

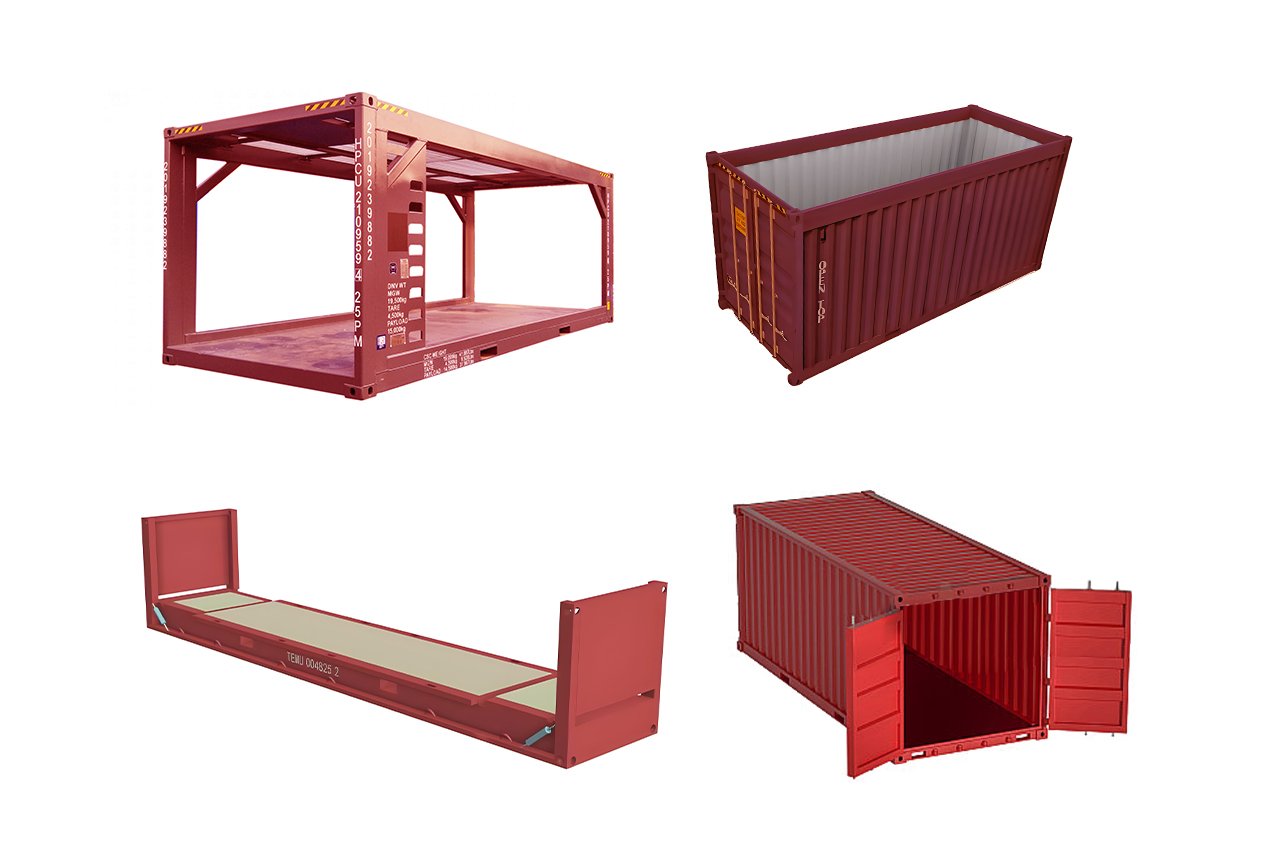

Cabinet type

Cabinet type, 3D loading model

Route Planning

Booking, route planning, and preliminary preparation Preparation before container loading

Container loading

special trailer, vacuum packaging, etc,Binding and fixation, wooden box packaging, ultra-low flatbed trailer

Customs clearance

Customs declaration and release,DAP, DDP post delivery service

Plant relocation transportation

Plant A factory relocation transportation plan involves the planning and coordination required to move equipment, machinery, and materials from one location to another. This plan typically includes various phases and tasks to ensure the relocation process is smooth and efficient. Below is a description of a typical transportation schedule for a factory relocation:

- Preparation Phase:

a. Assessment:Evaluate the current factory layout, equipment, and materials to determine transportation requirements.

b. Planning:Develop a detailed relocation plan, including timelines, resources, and budget considerations.

c. Vendor Selection: Identify transportation providers and sign contracts with them, such as logistics companies or specialized equipment movers.

d. Coordination: Establish clear communication and coordination channels among all stakeholders, including factory management, transportation providers, and relevant parties. - Equipment and Machinery Preparation:

Disassembly: Safely dismantle and disconnect equipment, ensuring proper labeling and documentation for reassembly.

Packing and Protection: Securely pack fragile components, sensitive machinery, and parts, providing appropriate cushioning or protective measures.

Inventory Management: Create an inventory list to track all equipment, machinery, and materials being transported, documenting their condition and location within the factory.

- Transportation Planning:

Route Selection: Determine the most efficient and feasible transportation routes, considering factors such as distance, road conditions, and any required special permits.

Loading Plan: Optimize the placement of equipment and materials in transport vehicles to maximize space utilization and minimize the risk of damage during transit.

Logistics Coordination: Schedule transportation vehicles, including trucks, trailers, or specialized transport equipment, based on availability and load requirements.

- Loading and Unloading:

Loading Preparation: Use appropriate restraints, covers, or containers to ensure equipment and materials are properly secured and protected during transport.

- Loading:Coordinate the timely arrival of transport vehicles at the factory site to ensure efficient and safe loading of equipment and materials.

- Transportation:Monitor and track the progress of each shipment to ensure adherence to the schedule and address any unforeseen situations or delays.

- Unloading:Coordinate the arrival of transport vehicles at the new factory location, ensuring a safe and orderly unloading process.

- Post-Relocation Evaluation:

Evaluation: Assess the overall success of the factory relocation, considering factors such as adherence to the schedule, cost-effectiveness, and any unforeseen challenges encountered.

Lessons Learned: Identify areas for improvement and document valuable insights and best practices for future reference.

It is important to note that the specific details of a factory relocation transportation schedule may vary depending on the size and complexity of the factory, the distance between the old and new locations, and any unique requirements related to the transportation of equipment and materials.

Customer reviews about Bentlee

User reviews from trustpilot

More Order Fulfillment Services Shipping from China

FAQ

OOG (Out of Gauge) cargo refers to oversized, overweight, or irregularly shaped shipments that cannot fit into standard containers. Common OOG solutions include Flat Rack and Open Top containers.

OOG containers are typically used for heavy machinery, construction vehicles, wind power equipment, steel structures, timber, long pipes, and precision instruments.

Yes. We provide professional reinforcement solutions such as wooden crating, steel wire lashing, vacuum packaging, and waterproofing to ensure cargo safety.

The cost mainly depends on cargo dimensions, weight, container type, shipping route, and reinforcement requirements. A detailed quotation will be provided after reviewing your cargo details.

No. With over 10 years of customs clearance experience and a 98% clearance success rate, we ensure smooth and reliable clearance for oversized and special cargo.

We offer end-to-end logistics solutions including transport planning, warehousing, crating and reinforcement, inland + sea transportation, customs clearance, and door-to-door delivery.